SELF LEVELING EPOXY

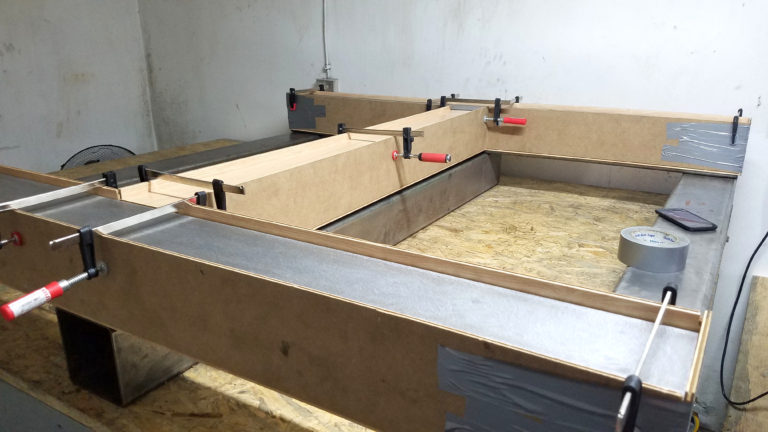

While it’s likely not worth it for the average DIY router build, if your steel is in poor shape dimensionally like mine was, you’ll likely get your moneys worth out of the process.

Equipment and Tools Needed

Prep

3. Epoxy – I used self-leveling epoxy that was designed for pours up to 1cm thickness. It was EPO 652. My goal thickness for the epoxy is about 3-5mm so it’s plenty.

5. Additional stuff – you’ll need a container to mix the epoxy in as well as some method to seal your form against the steel. I used silicone caulk to seal the edges of the form, but if you use such caulk ensure that you are using neutral cure, not acid cure, as acid cure will rust your steel as it dries.

Y Axis

10. DO NOT MOVE YOUR Y AXIS OR YOUR TABLE, YOU NEED IT TO STAY IN POSITION FOR COMPLETION OF THE X AXIS

X Axis

X Axis Theory

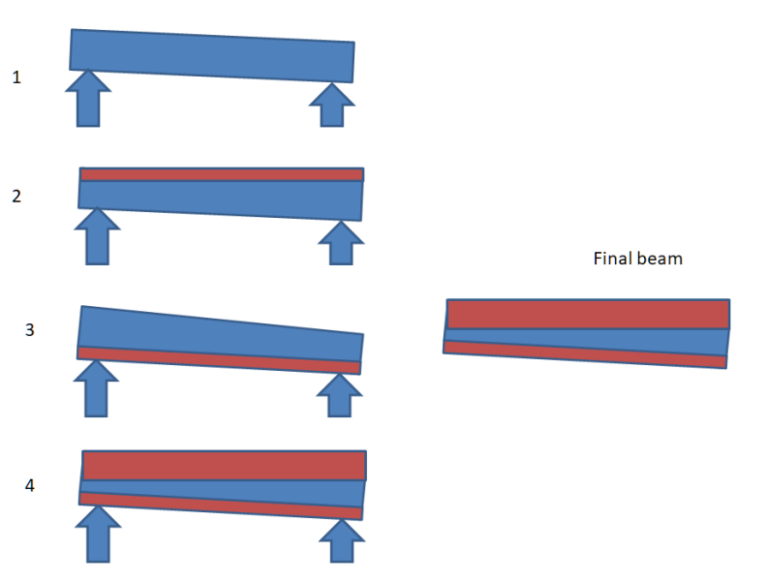

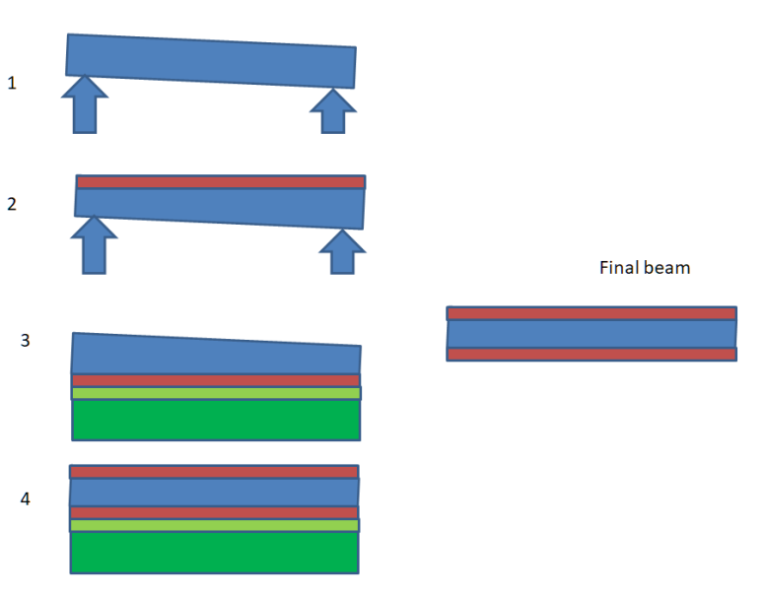

The X axis presents a unique challenge because it is double-sided. Here’s a breakdown of the problem at hand

This diagram demonstrates pouring epoxy on both sides of the X axis without a solid reference surface. Some error can be mitigated by flipping the beam 180 degrees after the first pour, but it does not eliminate error entirely. In other words, pouring epoxy onto the beam, and then merely flipping it over, does not necessarily result in a beam with two surfaces that are parallel with each other.

However, since in pouring the Y axis we already have one reference surface, we can pour the epoxy for side one by laying the beam directly onto the epoxy surface and then placing that surface against our existing Y axis surface as a “reference” so that we can achieve as close to a flat result as possible.

Execution

7. Once its been cured / sanded, you are complete.

Final Notes

Be careful with your epoxy surfaces. The important surfaces will be protected from damage by the steel once you place and bolt your rails and blocks in place. The relatively large surface area of the rail will not compress the epoxy, but if you drop your drill onto the epoxy before your rails are in place, it can gouge the surface. Small gouges and pits from bubbles are without consequence so long as they do not push material up above the general surface of the epoxy.

When it comes to the drill / tap / centerpunch steps, the epoxy surface is mostly without consequence. I used a carbide scribe instead of a traditional centerpunch for centerpunching into the epoxy, as it allowed me to create a nice divot in the surface of the epoxy without having to hammer too hard and potentially create a crack in the epoxy. When it comes to drilling and tapping, there was no real difference in my approach vs the non-epoxy surface.

For painting, the preferred method is to place the rails and blocks onto the epoxy, cover them completely with painters tape, and then paint the surfaces, so that you do not damage your reference surface you worked so long to create. This is preferably done once you have squared and straightened your rails, so that you do not have to shift the rails once the surface is painted.