LinuxCNC Configuration

Some tidbits that will help with LinuxCNC Configuration that I learned along the way, and my own current LCNC Config for an XYYZ kinematics machine.

My LinuxCNC Configuration and some tips/tricks I've discovered along the way

GitHub Link to my configuration

Stepgen PID

Your Stepgen P value, which shows up in your .hal file -

STEPGEN_MAXVEL = 208.33

STEPGEN_MAXACCEL = 7000

P = 500.0

I = 0.0

D = 0.0

FF0 = 0.0

FF1 = 1.0

FF2 = 0.0

BIAS = 0.0

DEADBAND = 0.0

MAX_OUTPUT = 0.0

Is inversely proportional to your servo period value.

SERVO_PERIOD = 2000000E.g. If you have a SERVO_PERIOD of 1000000, which corresponds to 1ms, then the P is 1000. If you have a 2ms SERVO_PERIOD, then P should be 500, and so on.

As best I understand, this has to do with how LinuxCNC compensates for error between the PC and the Mesa card.

Slow Jogging

# *** Slow Jogging***

loadrt mux2 names=xmux,ymux,zmux

addf xmux servo-thread

addf ymux servo-thread

addf zmux servo-thread

net slowselect <= halui.mode.is-manual

net slowselect => xmux.sel => ymux.sel => zmux.sel

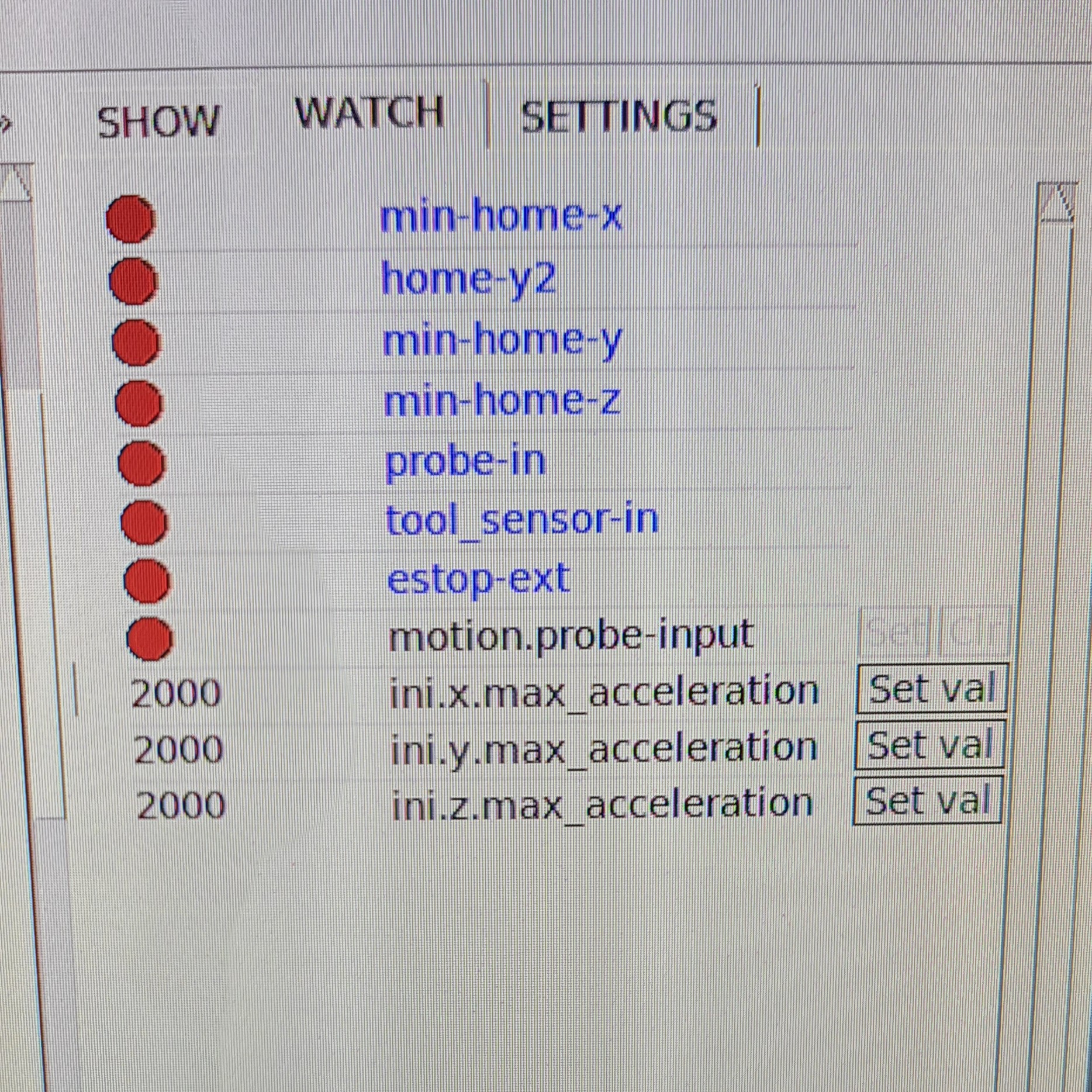

setp xmux.in0 [AXIS_X]MAX_ACCELERATION

setp ymux.in0 [AXIS_Y]MAX_ACCELERATION

setp zmux.in0 [AXIS_Z]MAX_ACCELERATION

setp xmux.in1 1000.0

setp ymux.in1 1000.0

setp zmux.in1 500.0

net xmux-sig xmux.out => ini.x.max_acceleration

net ymux-sig ymux.out => ini.y.max_acceleration

net zmux-sig zmux.out => ini.z.max_acceleration

This code snippet can be added to custom_postgui.hal in order to use different accel values when in jogging mode. This can be useful since the trapezoidal trajectory planner that LCNC currently uses can result in jerky movements, whether you are using a keyboard or an MPG.

Time for Probe Basic

# *** Add Time ***

loadrt time

loadrt not

addf time.0 servo-thread

addf not.0 servo-thread

net prog-running not.0.in <= halui.program.is-idle

net cycle-timer time.0.start <= not.0.out

net cycle-seconds qtpyvcp.timerseconds.in <= time.0.seconds

net cycle-minutes qtpyvcp.timerminutes.in <= time.0.minutes

net cycle-hours qtpyvcp.timerhours.in <= time.0.hoursIf you're using Probe basic, this makes the timer field work properly

Spindle Load Percentage

More details on the LinuxCNC Forum, but this (in combination with the the manually made load_conv.comp mentioned on the forum) makes the spindle load meter work properly.

For instance, my load_conv.comp file looks like

component load_conv "calculates percentage of load based on motor Amps";

pin in float amps;

pin out float percent;

function _;

license "GPL"; // indicates GPL v2 or later

;;

#include <rtapi_math.h>

percent = round(amps/0.12);Change 0.12 to be how many amps your spindle can handle at max load (0.12 is 12a in my case)

Open terminal and run

halcompile --install load_conv.comp`If HalCompile isn't installed, make sure to install the linuxcnc-dev tools package

Then add the following to your HAL.

A couple notes:

- The compiled file saved to /usr/lib/linuxcnc/modules is named load_conv.so, and it must be loaded in HAL as load_conv. However, the pin added with addf must be load-conv, with a hyphen instead of an underscore.

- The pins are load-conv.0.amps and load-conv.0.percent

# *** Spindle Load Percent ***

loadrt load_conv

addf load-conv.0 servo-thread

setp qtpyvcp.spindle-load-indicator.max-val 100

net spindle-current => load-conv.0.amps

net spindle-load qtpyvcp.spindle-load-indicator.in-f <= load-conv.0.percent

net spindle-speed-fb => qtpyvcp.spindle-encoder-rpm.inProbing Hardware

This enables me to use both the tool setter and the probe with LinuxCNC. I use the subroutine from TooTall18T that's available on GitHub

# *** Probe HAL ***

loadrt or2 count=2

addf or2.0 servo-thread

addf or2.1 servo-thread

# or2.1 belongs to mpg.hal

net tool_sensor-in <= hm2_7i76e.0.7i76.0.0.input-14-not

net probe-in <= hm2_7i76e.0.7i76.0.0.input-13-not

net estop-ext <= hm2_7i76e.0.7i76.0.0.input-15-not

net tool_sensor-in => or2.0.in0

net probe-in => or2.0.in1

net probe-tool or2.0.out

net probe-tool => motion.probe-input